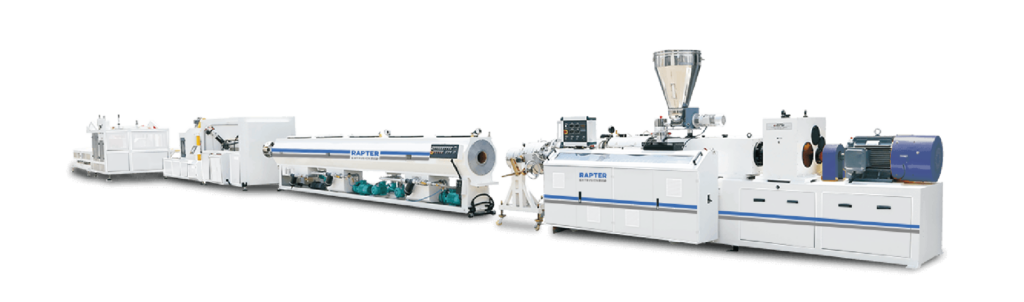

PROCESSING MACHINES

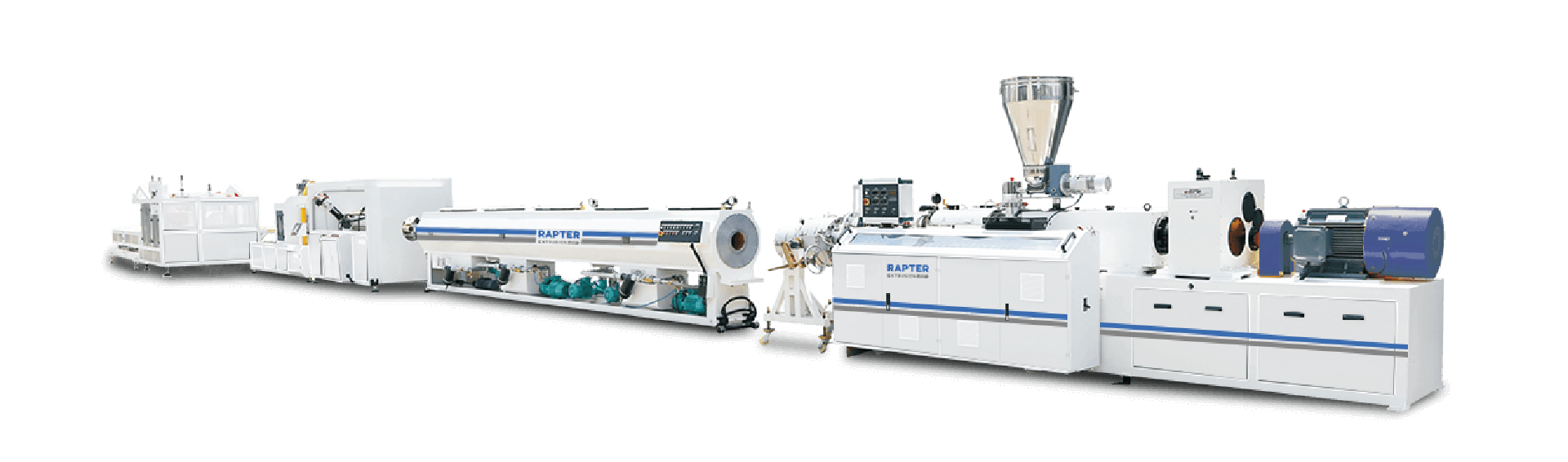

EXTRUSION MACHINE WITH DOWNSTREAM ACCESSORIES - PVC, CPVC, UPVC, HDPE, PE & PP

Our pipe extrusion lines provide the best-in-class Twin Screw & Single Screw technology for the PVC, CPVC, UPVC,

HDPE, PE & PP segments.

We offer far-ranging pipe diameters for agriculture, drip irrigation and potable drinking water solutions.

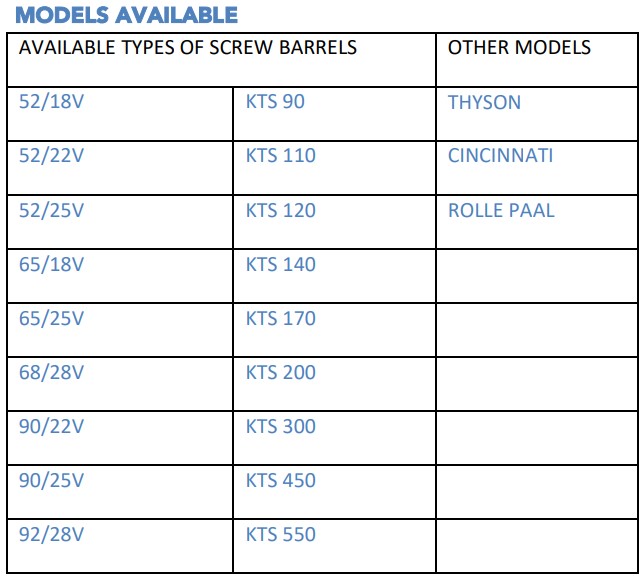

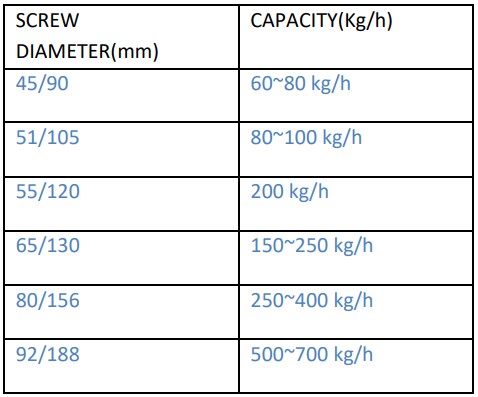

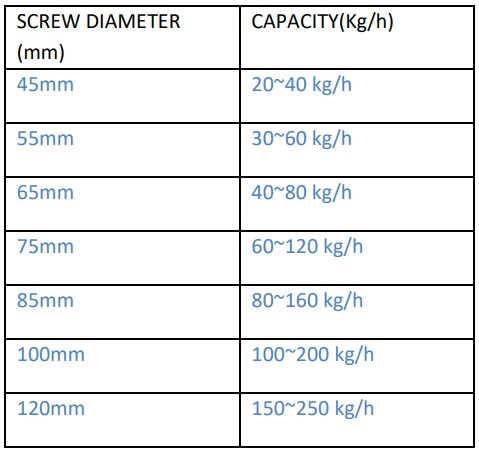

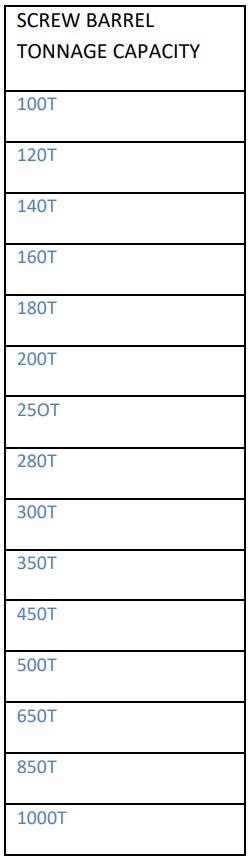

SCREW AND BARRELS

Parallel Twin screw

Conical Twin Screw

Single screw barrel

Injection Moulding Screw Barrel and accessories

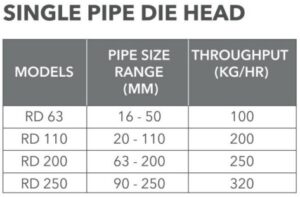

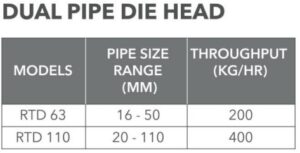

PIPE EXTRUSION DIE HEADS

Our Die design ensures uniform pipe thickness throughout the pipe High volume, low pressure design ensures wider thickness range High efficiency Twin Die heads for smaller diameter pipes

Maximum utilisation of Die head from 80% – 100%

Die heads for PVC, UPVC, CPVC, SWR & Column Pipes

CALIBRATOR/VACUUM & PRESSURE SIZER

Sizes from 19mm to 400mm

Aluminium cooling jacket provided

Heat resistance with maximum life span

High precision for better pipe production

Made of special stainless steel with excellent properties

Intensive intake cooling ensuring the quality of the surface

*Also available in Gun metal

*Pressure Sizers for pressure pipes available

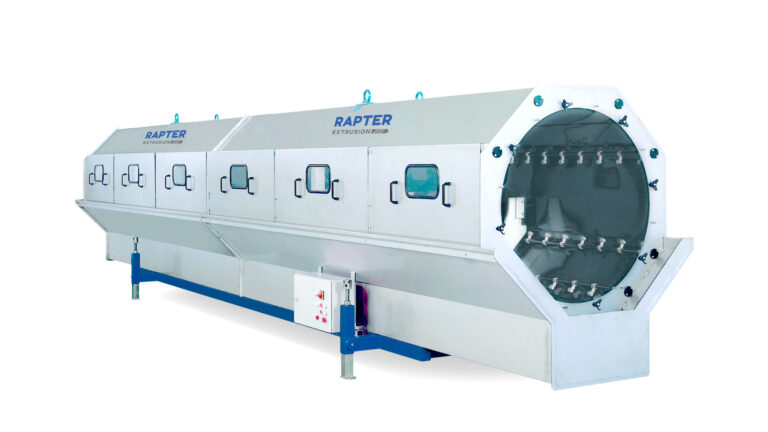

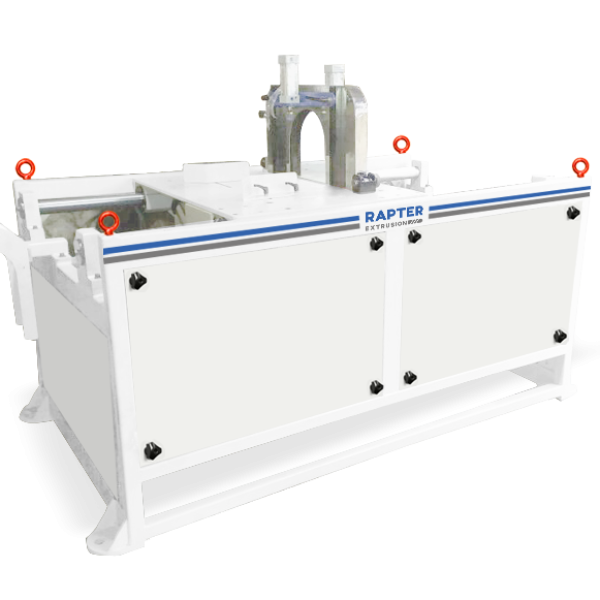

COOLING TANKS

Vacuum Tank

Higher production with comprehensive cooling system

Precise temperature, vaccum & water level control

Motor controlled tank axial movement for easy handling

Guided rail provision for Axial & Transverse movement of the tank

Dual vaccum spray tanks for dual pipe extrusion line

Transparent filters for online cleaning

Self-cleaning spray nozzle

Aluminium cast lids

*Spray tank material: SS304

*Spray tank Bottom frame: MS

Spray Tank

Rigid frame construction

Transparent filters to make sure clean water enters into the tank

Inlet and outlet watertight seal around the pipe

Low water consumption

Reliability and maximum process control

Simple height adjustment

NAME PRINTING MACHINE

Traditional roller-type

Printing machine

Easily changeable roller dies

Ink-jet printing machine with control system

Clogging free machine

Printing design can be customized with different color inks

Accurate printing with smart laser printer

Easy maintenance

Problem free control system

HAUL OFF / TRACTION UNIT

Haul-offs with 2 caterpillar chains, with rubber pads & aluminium rails

Works with high extrusion speed

Tiltable upper caterpillar chain

Caterpillar chains driven by A.C. motor with gear box

A.C. drive provided to achieve highest precision and stability

Synchronisation with any type of extruder

Optional – thick thin control process

Optional – PLC control system

*Single Pipe and Dual Pipe traction unit for extrusion line

AUTOMATIC CUTTING MACHINE

Carbide tipped circular saw for thick pipe

Diamond blades for thin pipe

Pneumatically operated carriage movement

Maintenance free top clamping

Swarf removal system

Carriage movement on linear motion bearing

Dual cutter for dual pipe extrusion line

Rust resistant top plate in aluminium

Optional – PLC based control system

*Available Cutter size: 110mm, 200mm, 250mm

AUTOMATIC AND MANUAL SOCKETING/BELLING MACHINE

Smooth socket finish for solvent cemented or rubber gasket

Equipped with two ovens with double chamber

Limited energy consumption and minimum overall dimensions

Heating system with thermo regulated oven

Even heating of the pipe both inside and out

Forming system with mechanical mandrel with expandable inserts

Air/water cooling system

Reduction of labour

Increased productivity

Manual socketing also available

*Socket machine range: 1/2” to 10” inch