POST PROCESSING MACHINES

CNC CASING PIPE THREADING LATHE MACHINE

Brilliant cutting capability provides high productivity

Cost efficient and time saving

Abnormal load detection decreases damage to the machine

Advanced safety features

Built-in motor equipped on the main spindle

FANUC control system used

User friendly design

Shortened cycle time when compared to other machines

*Pipe threading range: 1” – 10” inch

CNC COLUMN PIPE THREADING LATHE MACHINE

Heavy & Rigid Structure

Easy operation

FANUC control system used

User friendly design

Brilliant cutting capability provides high productivity

Abnormal load detection decreases damage to the machine

Advanced safety features

FANUC control system used

*Pipe threading range: 1” – 5” inch Column pipe

* Spindle drive – AC Motor/ Servo motor equipped on the main spindle

PVC CASING PIPE SLOTTING MACHINE

Movement controlled by servo motor

Touch screen for machine operation

Dust free environment

High priority for workers’ safety

Less human interference

Rigid structure to avoid vibrations

Automatic pipe indexing unit

Designed to handle longer and heavier pipes

*Pipe threading range: 1” – 10” inch

CNC COUPLER CUTTING MACHINE

3.4m bed movement with precision bearings

HMI Touchscreen display

Servo controlled motion system

Dust collector for a clean environment

Aluminium jaws for soft clamping

Safe and hassle-free operation

Cost-efficient with higher production

4 times higher production than other machines

Optimised design for minimal space occupancy

*Cutting size min/max: 1/2″ to 5″

Column pipe coupler

Fabricated coupler

SWR coupler

Conduit elbow coupler

SOLVENT CEMENT MIXING MACHINE

Vortex free mixing

Stainless steel tank

25 – 1000 litres capacity

Easy dispensing of solvent

Gravity feeding resin hopper

Double impeller mixing method

Solid structure without vibration

Sturdy gear box with motor for heavy load

*VFD provided to run the machine at variable speed

PLASTIC SCRAP GRINDER MACHINE

Optimized cutter saddle

No tools required for maintenance & cleaning up

Low power, noise and energy saving

Heavy loaded wheel

Half round mesh and low power consumption

User friendly, longer running life

Cutter blades made of hard steel

Can crush PVC, HDPE, LDPE, PP, ABS and so on

Quick and easy blade setting & changing system

*Output range : 60 – 300kg/hr

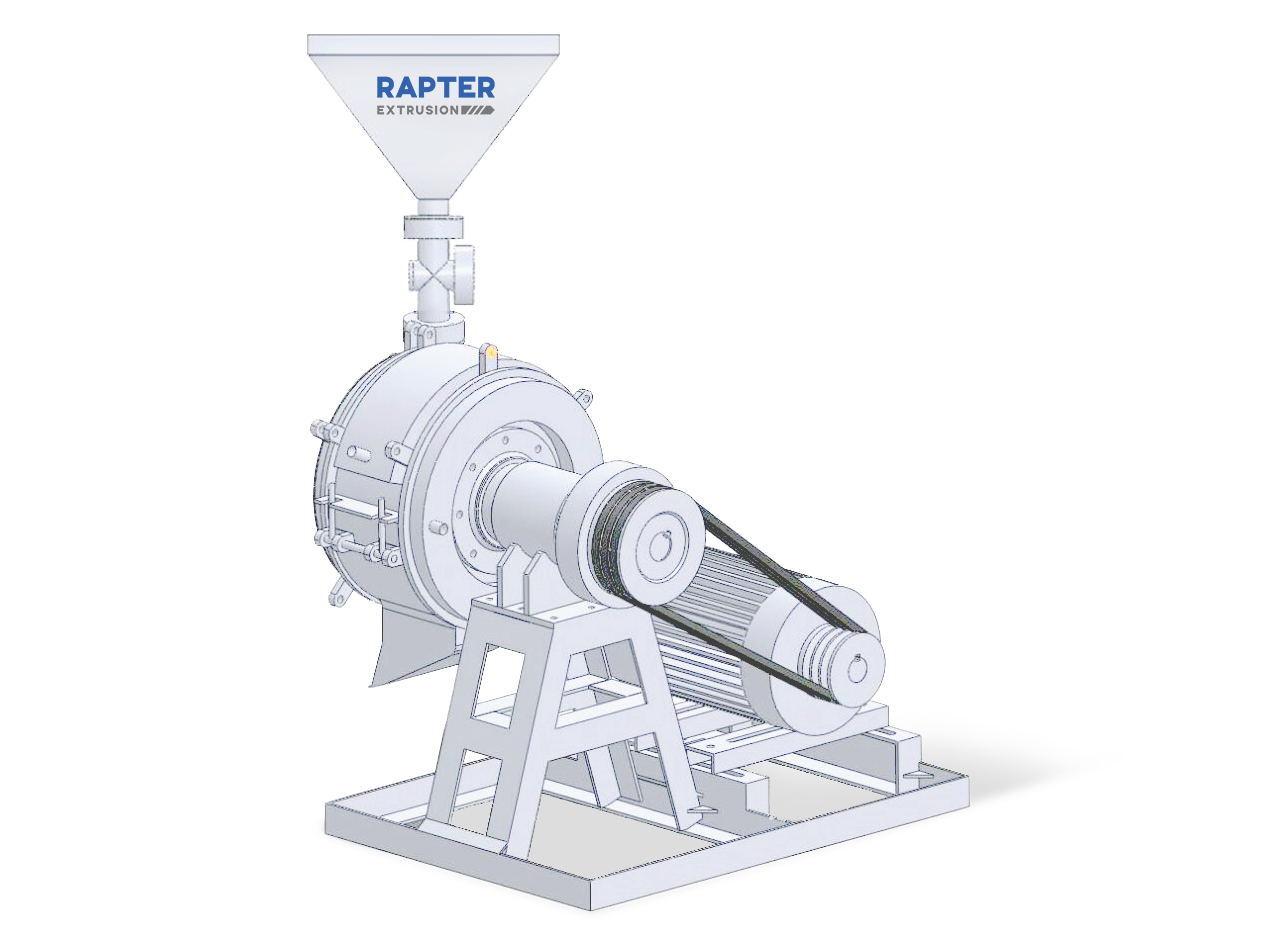

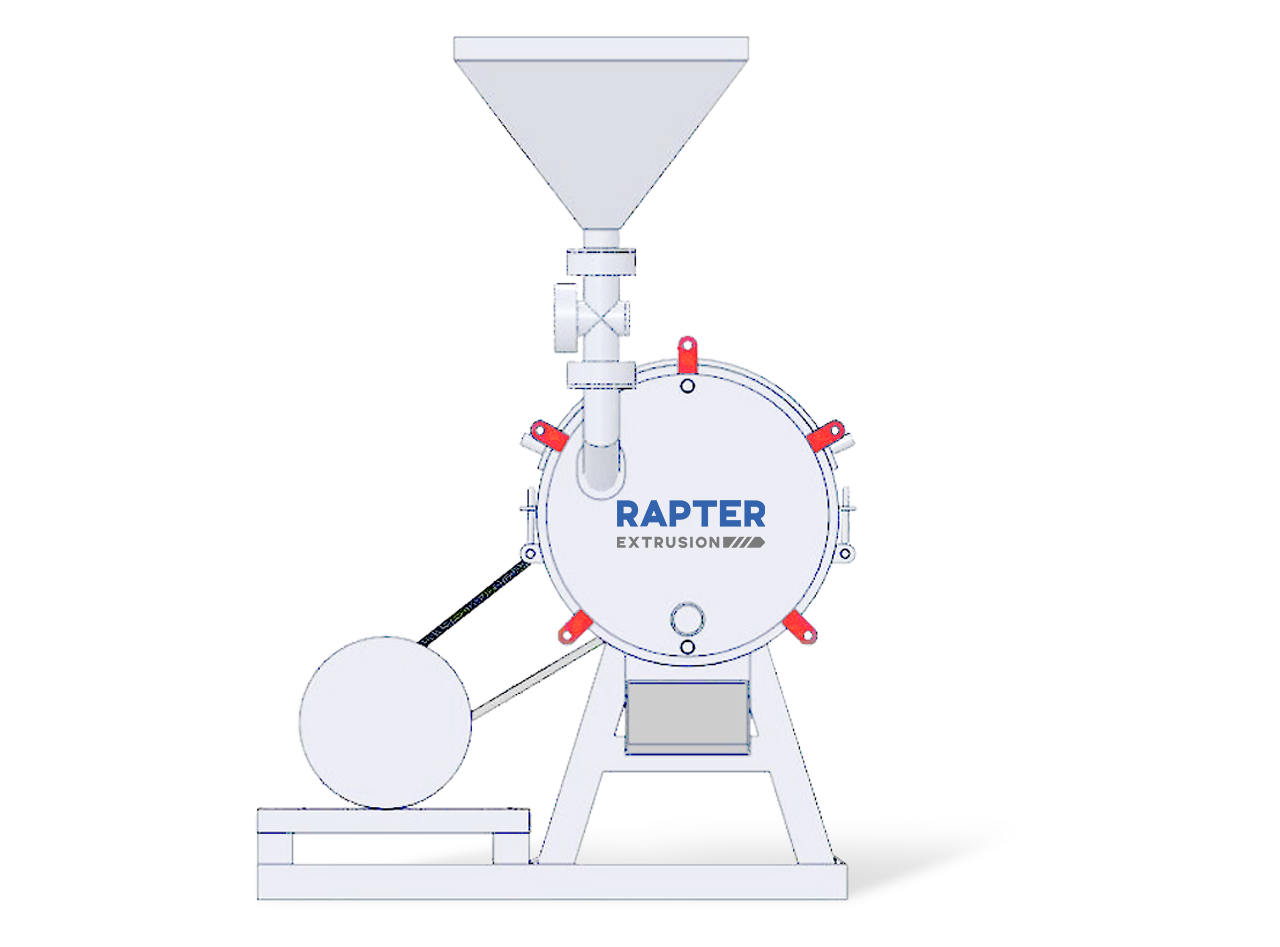

PULVERIZER HAMMER TYPE

Rigid structure design

Motorised hopper feeder

A.C. motor with drive provided

Lower energy consumption

SKF bearings used for main spindle

Grinds both low and high-density plastics

Less maintenance and zero additional product cost

Cooling system for bearing housing and pulverizer drum

Optional dust free blower with cyclone for material collection

*Output range: 40 – 150kg/hr

*Hammer type and disc type Pulverizer available